Due to the physical nature of work in cannabis cultivation facilities, these jobs can prove quite dangerous. Whether it be daily duties like watering or harvest-related chores like hanging plants, Cultivation Technicians have many ways to get injured on the job.

As authorities on light-lifting and harvest technology, Lift and Grow knows well the financial risks associated with workplace injuries in commercial cannabis gardens. In fact, by developing automated, machine solutions for dangerous garden chores, Lift and Grow eliminates many of the ways people can get hurt at work.

Common Injuries in Cannabis Cultivation Facilities

Because cannabis cultivation jobs are physically demanding, insurance companies categorize them similarly to positions in traditional agriculture. While rates vary between indoor and outdoor operations, cultivation jobs are considered some of the most dangerous in the cannabis industry.

Musculoskeletal Disorders (MSDs)

As the U.S. Bureau of Labor Statistics explains, “Musculoskeletal disorders (MSDs), sometimes called ‘ergonomic injuries,’ occur when the body uses muscles, tendons, and ligaments to perform tasks, often times in awkward positions or in frequent activities which over time can create pain and injury.”

MSD injuries are particularly problematic for indoor growers. To this end, repetitive motions like crouching to work beneath grow lights or squatting to water plants can have serious consequences when repeated continuously, day after day.

Soft Tissue Injuries

Soft tissue injuries refer to damage done to muscles, ligaments, and tendons in the workplace. Examples of soft tissue injuries include common muscle sprains and severe soreness. Because soft tissue injuries are more difficult to diagnose than MSDs, they are often overlooked in the workplace.

When employees are forced to stretch awkwardly to complete chores like cleaning the bottoms of plants, it puts them at risk of soft-tissue injuries.

Broken Bones & Fractures

It goes without saying that it takes quite a bit of force to break or fracture a bone. Nonetheless, when a team member experiences an injury of this severity, it means they will be missing a long period of work to recover.

Ladder work is one of the biggest culprits for broken bones and fractures on the job. When employees climb on ladders to complete chores like hanging plants during harvest, it puts them at risk of breaking bones if they fall.

It’s for reasons such as this that ladder falls are responsible for more deaths than any other type of injury in the construction industry.

Expenses often Associated with Dangerous Workplaces

There are several key ways that employee injuries in cultivation facilities can negatively impact your bottom line.

Workman’s Comp Expenses

No matter where your cannabis cultivation facility is located, you need some type of workman’s comp insurance. Generally speaking, your company pays annual premiums to cover workman’s comp insurance – with rates ranging anywhere from 2%-6% of salary expenses. If you have a consistent poor safety record at your cultivation facility, be prepared for annual rate increases.

Injuries on the Job

If you have an employee injured on the job, you are responsible for covering their wages for the entire time they miss work. Moreover, you must also account for expenses related to training new team members, as well as other administrative fees.

In the unfortunate event that an employee sustains a serious injury involved with ladder work or something similar, they might miss months of work. This type of injury could easily cost you thousands of dollars over time.

OSHA Certifications

Depending on the size and scope of your cannabis cultivation operation, you also need to pay to get your team OSHA certified. Exactly what type of safety training your operation needs will differ depending on the rules and regulations of your particular state market.

To illustrate, Colorado requires a “General Industry 10-hour course” that covers “industrial hygiene, ergonomics, walking-working surfaces, fall protection, hazard communication, electrical safety, emergency action plans, and record keeping and reporting requirements.” This required Colorado OSHA training for cannabis cultivation work costs $50 per employee.

How to Minimize the Risks of Working at a Dispensary

As can be seen, there are many ways that employees are at risk working iDn cannabis cultivation facilities. Not only are injuries extremely problematic for your employees, but they also directly impact your bottom line. In the end, taking extra steps to ensure employee safety is a great way to keep your team happy and motivated, while also reducing your financial risk.

Process Improvement

By employing process improvement measures, you assess daily workflows to uncover potential safety hazards. In cannabis cultivation facilities, a great approach is to start by looking at common injuries such as MSDs and broken bones. Next, have a critical look at daily chores such as watering, spraying, and facilities maintenance to uncover any repetitive tasks where such injuries might happen.

Once you have identified key ways where people might get hurt on the job, you can implement new systems that avoid risky behavior.

Employee Training

Once you have audited your workflow and created safer methods, it’s time to put this new information into action within your cultivation operation. This next phase begins with writing standard operating procedures (SOPs) that give specific instructions on how to safely complete garden-related chores.

With SOPs in hand, you can train employees on workplace safety in a uniform and intelligible fashion. Please note that effective employee training begins with management and is then communicated to other employees.

Facilities Design & Automation

By increasing the amount of automation in your cultivation facility, you will lessen your dependency on human labor. In turn, the fewer manual chores in your operation, the fewer opportunities people have to get hurt at work. This notion is particularly true for excessively dangerous jobs like ladder work.

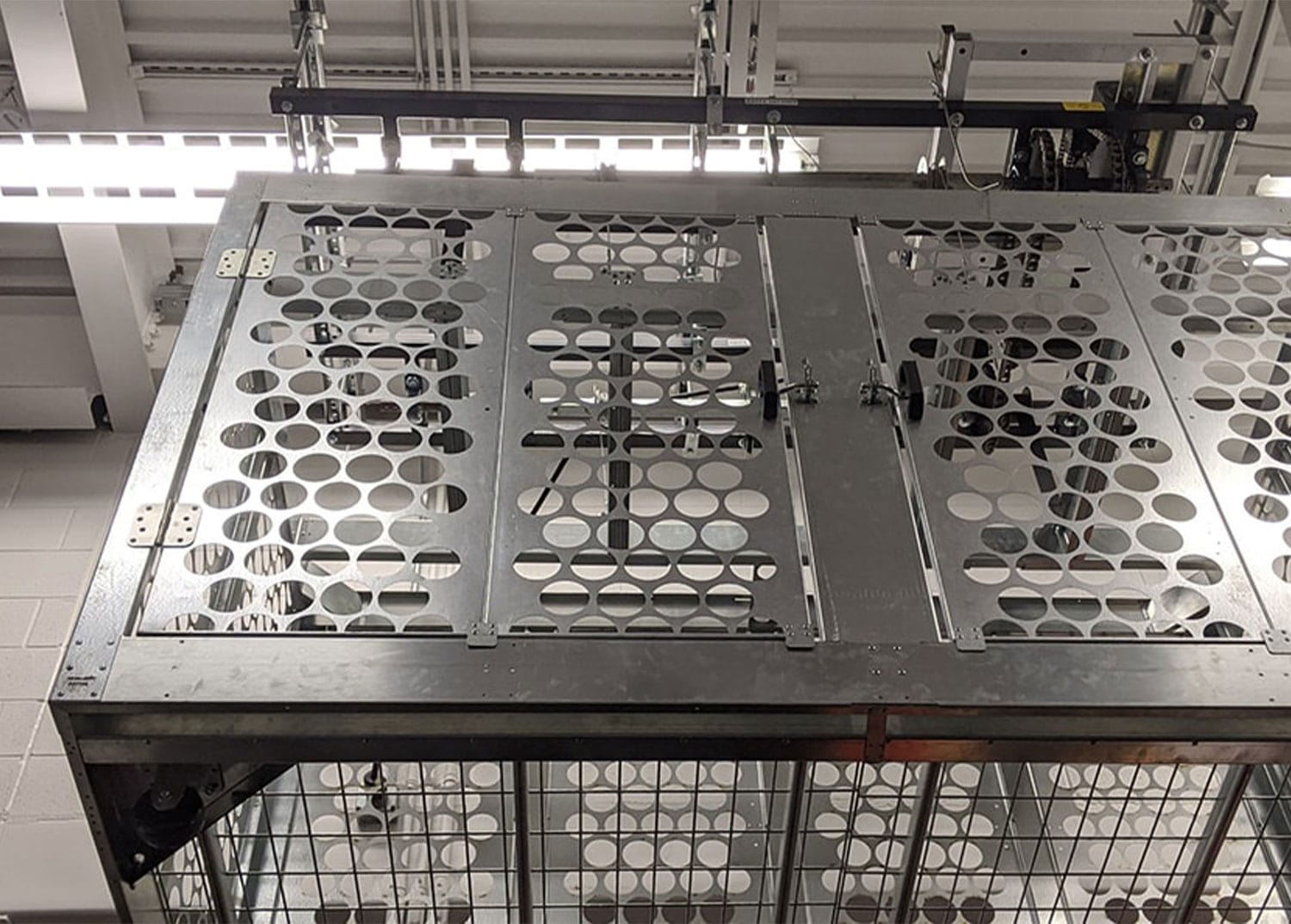

Lift and Grow has developed several technologies to increase the yield, shorten grow time, shorten the drying cycle, and maintain, or increase the quality of your plants and the safety of your workers. Our Light Lifting system or our patented H2P Drying solutions will give you the ROI you need to stay competitive in today’s environment.

Ready to Make Improvements? Talk to Lift & Grow Today!

As the cannabis industry continues to grow more competitive, producers are beginning to understand the monetary value of safe working environments. Whether it be workman’s comp insurance or paid leave for injured employees, unsafe working conditions directly impact your bottom line.

Please Contact Us to discuss creating a safe work environment at your cultivation operation.